With 41,300 GT, 180 meters long, 30,5 meters wide, the ship offers a 2.516-meter long parking facility, or enough space for about 180 trailers.

She is powered by four 9.600 kW engines offering a maximum speed of 24 knots. Passenger facilities include two large bars, one à la carte and one self-service restaurant, a cinema, a children’s play area and a sun deck. There is also a kennel room. There are 200 cabins in total, 150 four bed types and 50 double bed cabins, as well as the air seats, the company has a vessel which should facilitate a stress-free crossing for the 750 passengers it can accommodate.

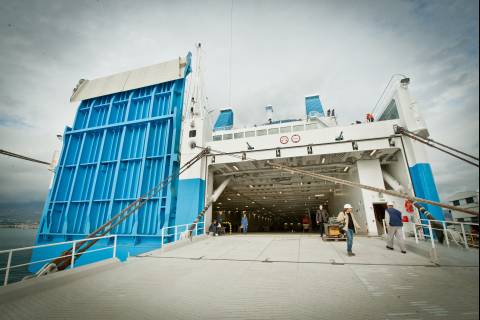

Three of 12 decks are reserved for its freight capacity. Passengers have a dedicated car deck, with a ramp used solely for passenger vehicles, and direct access to the accommodation spaces. All vehicle decks are open with no pillars in order to simplify loading. It allows easy maneuvring in the garage spaces, due to the fact that the ship is quite wide (30.5 m beam).

The passenger flow is designed to be very convenient, with the reception situated on Deck 8, just above the car deck. From the reception, easy access is provided for the passengers to reach their cabins on decks 8 and 9. Restaurants and bars are located on decks 9 and which makes facility locations logical for the passengers.

Bureau Veritas is classing the 180m-long vessel to its highest comfort class, Comf 1.

The vessel provides an easy and convenient journey for disabled passengers. Facilities include lifts and escalators, public areas are wide and are without obstructions, all onboard furniture had to have rounded edges to meet these criteria. Additionally, the vessel has a helideck.

Another important regulation the build had to adhere to was the Solas 2009 convention relating to damage stability. This means that the ship must attain required subdivision index, where the probability of the survivability of the ship in different damage conditions for the entire range of operational draughts is calculated. More than 420km of piping has been installed on board and all doors in the machinery spaces are watertight.

The vessel is divided into four vertical safety zones which are monitored by cameras. The engine room has been subdivided into four compartments. One compartment contains the four Wärtsilä 8L46FM common rail engines, another house the auxiliary engines, the third contains the oily water separator, the pumps and the Hyde Marine ballast water treatment system, and the thermal oil boiler is in the final compartment.

The ballast water treatment system can process 300m3 of ballast water per hour. Energy efficiency and the environment were major considerations for this vessel. The Wärtsilä engines are designed with a low fuel consumption level and meet IMO’s Tier II standards for low-NOx emissions. Ro-Pax ferry uses between 20 and 30 per cent less energy than older ropaxes and is certified to BV’s Clean Ship notation, signifying that all emissions are controlled and minimized.

PPG’s silicon antifouling hull coatings also mean that less fouling adheres to the hull, creating a smoother passage through the water that increases speed by between 2 and 3 percent. The ship also carries BV’s DPS notation, signifying redundant propulsion and steering.

The propeller shaft is taken outside of the hull to enable the ship to reach its service speed of 24 knots. This is the second ship in Europe installed with the flex-stern tubes technology. Ferry has to cope with side winds of up to 40 knots on its Mediterranean crossing, therefore good maneuvering capability was a high priority. Vessel has a CP propeller, Rolls-Royce bow thrusters, and Becker rudders to deal with this strong wind.